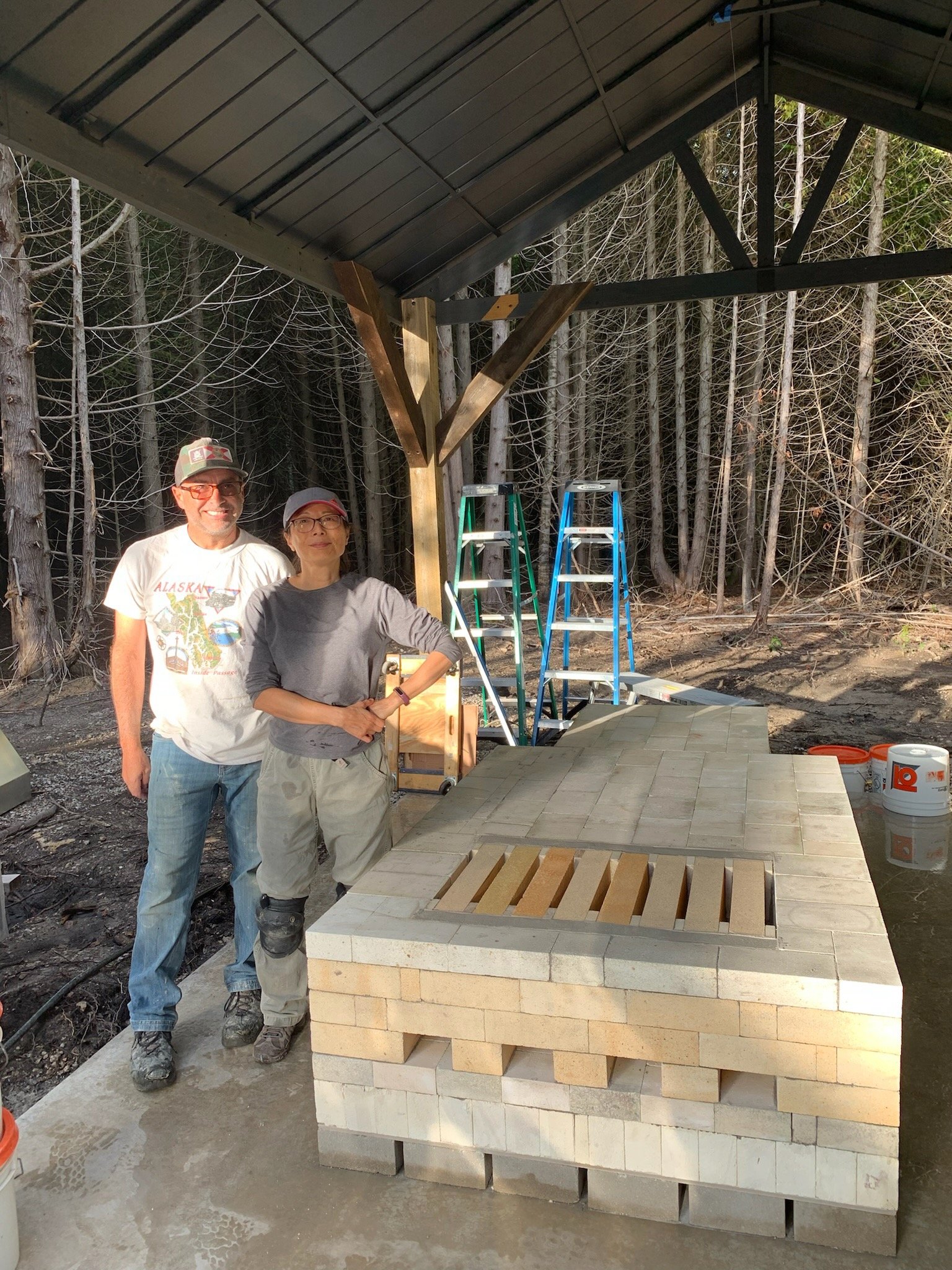

Hybrid Gas/Wood/Soda Kiln Bailey's Harbor, WI

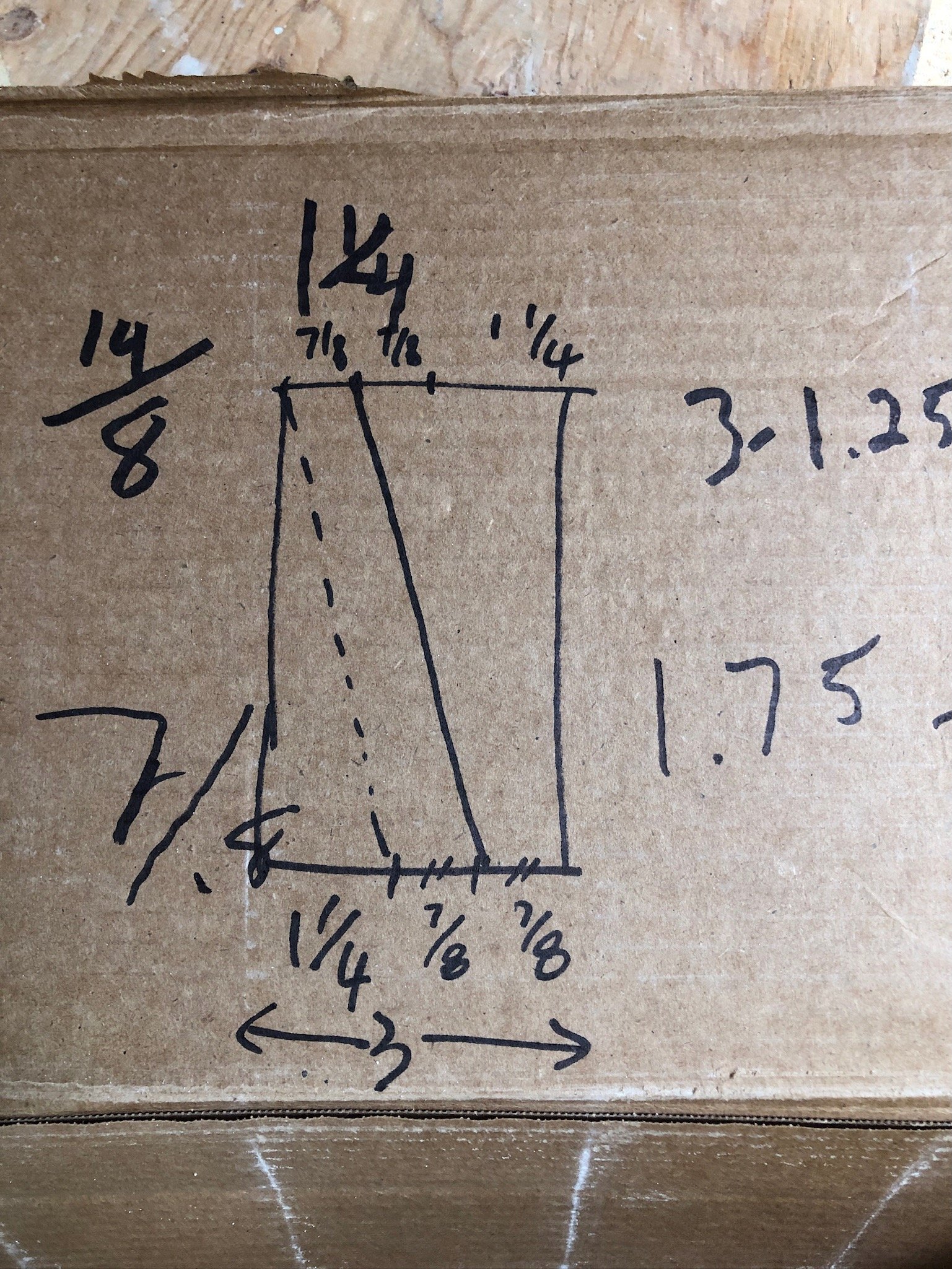

30 Cu/ft Caternary Arch hybrid kiln with drop down ash pit, brick grate, LPG 400K BTU x2 power burners, center hinge pin swing door, and rolling stoke hole doors. We used Super 75 mullite for the floor, Clipper Super Duty High Alumina #1 arch, Clipper Super Duty High Alumina walls, Seneca 60P grate and flue, BNZ 2660 for the door, BNZ 2500 for cold face insulation/sub floor, and Alsey medium duty (chimney above damper) to build this kiln. The arch is 4.5” hard brick, 3” BNZ 2500, 2 layers 6# 1” fiber, chicken wire mesh, 1” of 80 lb scratch coat sanded with fiber stucco/3 gallon vermiculite custom mix for skin coat. We installed 2x 400k btu/hr burners to bring the kiln to cone 10 in 12 hrs firing time. Interior dimensions hold 3 stacks, 12x24 shelf stacks. 1/4” mild steel framing ranging from 3” to 5” give this kiln and swing door structural integrity. Rolling stoke hole doors make burning wood easy, and this kiln can burn about 3/4 cord of split hardwood in 15 hrs from 1500-2300 degrees with a 10 hour hold at temp to build ash. Many thanks to Dave, Elizabeth, Bill, and May for your help, company, and hospitality during this memorable kiln build. The build was 12 days, and we fired the kiln successfully in 24 hours to Cone 10, burning about 3/4 cords of wood.